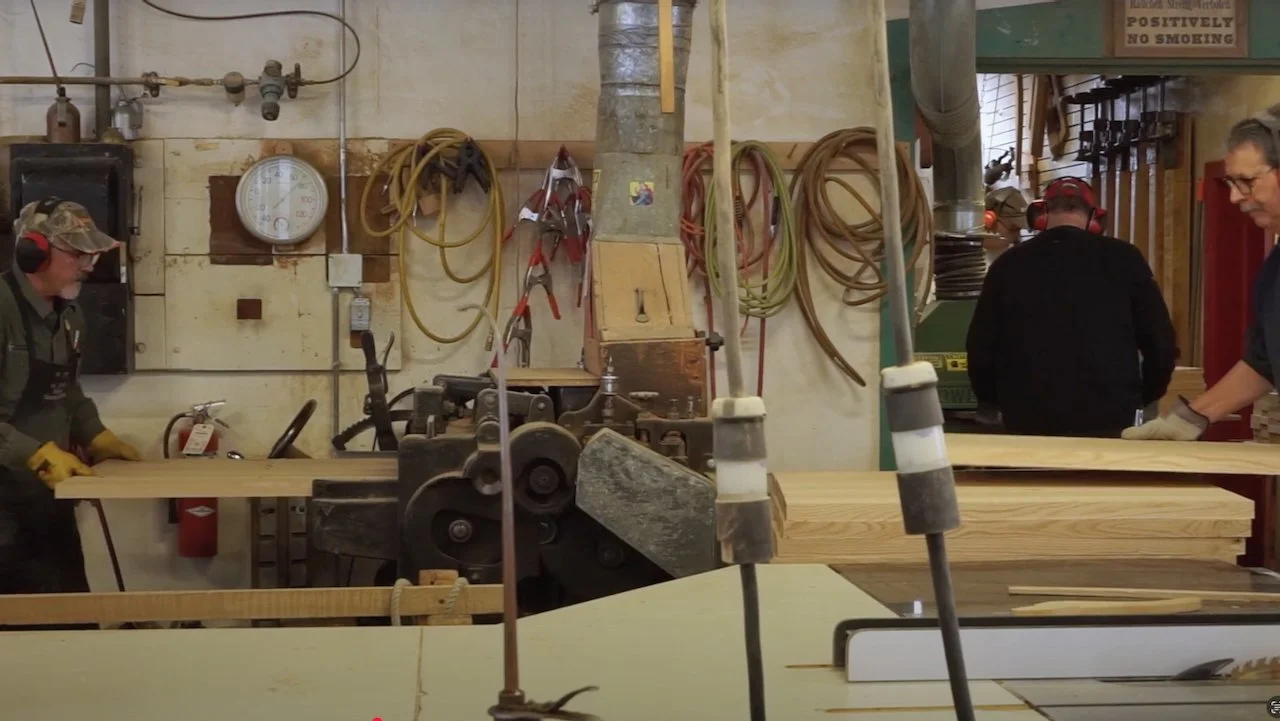

Ryan Kutter, Lead Woodworker

New woodworking equipment is not entirely fool proof. Even with digital controls, instant-stop safety features, and sealed motors that ask for little maintenance, we are always able to test them with new foolishness. Some of our legacy equipment, the planers, jointers, and mortising machines from 80-100 years ago, suffered no fools.

As we transitioned to the new Woodshop two years ago, we made some difficult decisions about which machines to bring along and which familiar contraptions to leave behind for reasons of safety, maintenance or efficiency. A centerpiece of the old shop was Bertha, a 30” planer built in 1907.

Bertha occupied the central space in the shop and was used on a nearly daily basis. Anytime new lumber was brought into the shop or boards needed to be thinned, they passed through Bertha’s teeth.

Operating Bertha was a ritual. A dozen or so oil-pots and shafts needed to be oiled before you thought about turning the planer on. Check that all was clear from the gears and wide belts that would flap and rattle. Open the vent and switch on the dust collector to prepare for the blizzard of shaving soon to fly. Review the safety protocols once more with your assistant who would be “catching” boards on the other side. Turn the crank to set the blade height. Push the contact lever up to bring enough power to set the machine into commotion, then quickly pull it down to hold it in operation.

By now, things are getting noisy. Pull the clutch to engage the rollers and blades. Feed in the first rough board and watch it emerge smooth out the other side. At this point the office workers upstairs might wander down to ask if we could hold off until their meeting ended, because they couldn’t hear themselves think. (But really, were their discussions really more productive than woodworking?). Perhaps that was our cue to change out the blades for a cleaner, quieter cut, and a good excuse to take a break while their meeting wrapped up.

Fortunately, Bertha was not turned into scrap metal when its time in the Woodshop was complete. Volunteers from the Stearns County Pioneer Club saw that the planer was in great shape after all the years and came to pick it up (prying, pushing, puzzling over basic physics, grunting, sweating and finally hauling it out the door before loading it with a forklift.). Bertha now lives at their fairgrounds in Albany, about 10 miles away. For the past two Albany Pioneer Days festivals Bertha has been on display, fully operational, planing boards once again for demonstrations and local projects.

It’s been nice to visit the old machine, to see the crowds that gather around it each fall and to know that the belts are mended and surfaces are free from rust. We now make sawdust and chips in quieter ways but still end the day with slivers in our hands and the same satisfaction in seeing fresh boards roll out, ready for new projects.